Introduction:

Centrifugal water pumps are widely used in automobile engines. Its basic structure consists of water pump housing, connecting disc or pulley, water pump shaft and bearing or shaft-connected bearing, water pump impeller and water seal device and other parts.

working principle:

The engine drives the water pump bearing and the impeller to rotate through the pulley, and the coolant in the water pump is driven by the impeller to rotate together. At the center of the impeller, the coolant is thrown out and the pressure is reduced. The coolant in the water tank is sucked into the impeller through the water pipe under the action of the pressure difference between the inlet of the pump and the center of the impeller to realize the reciprocating circulation of the coolant.

The bearings that support the water pump shaft are lubricated with grease, so it is necessary to prevent the lubricant from leaking into the grease and emulsification of the grease, and also to prevent the leakage of the grease. The sealing measures for the water pump to prevent leakage include water seals and gaskets. The water seal dynamic seal ring and the shaft are installed between the impeller and the bearing through interference fit, and the water seal static seal seat is tightly press-fitted on the casing of the water pump, so as to achieve the purpose of sealing the coolant.

The water pump housing is connected to the engine through gaskets and supports moving parts such as bearings. There is also a drain hole on the water pump housing, which is located between the water seal and the bearing. Once the coolant leaks through the water seal, it can be leaked from the drain hole, which has prevented the coolant from entering the bearing cavity, damaging the bearing lubrication and rusting the components. If the coolant still leaks after the engine is stopped, the water seal is damaged.

Drive of the water pump:

It is generally driven by the crankshaft of the engine through the V-belt. The transmission belt is surrounded between the crankshaft pulley and the water pump pulley. As soon as the crankshaft rotates, the water pump shaft rotates, and the water pump shaft drives the impeller to rotate, thereby converting mechanical energy into hydraulic energy.

The impeller is the core of the pump's work. The movement of the impeller itself is very simple, and it just rotates with the shaft. However, due to the action of the blades, the movement of the liquid in the impeller is very complicated; on the one hand, it is involved in the movement with the rotation of the impeller, and on the other hand, it is continuously thrown out of the rotating impeller under the driving of the blade, that is, the movement relative to the impeller. Therefore, the outer diameter of the impeller, the height and angle of the impeller blades, and the gap with the pump casing directly affect the performance of the pump.

If you also need a car water pump, you can contact us!

ABOUT US

Wenzhou Oustar Electrical Industry Co., Ltd. was founded in 1995 with registered capital 6.33millon dollars, covering area of 38000 square meters, is a modern scientific and technological sino-foreign joint venture, our products covers two categories of automotive electronics and household electrical appliances.

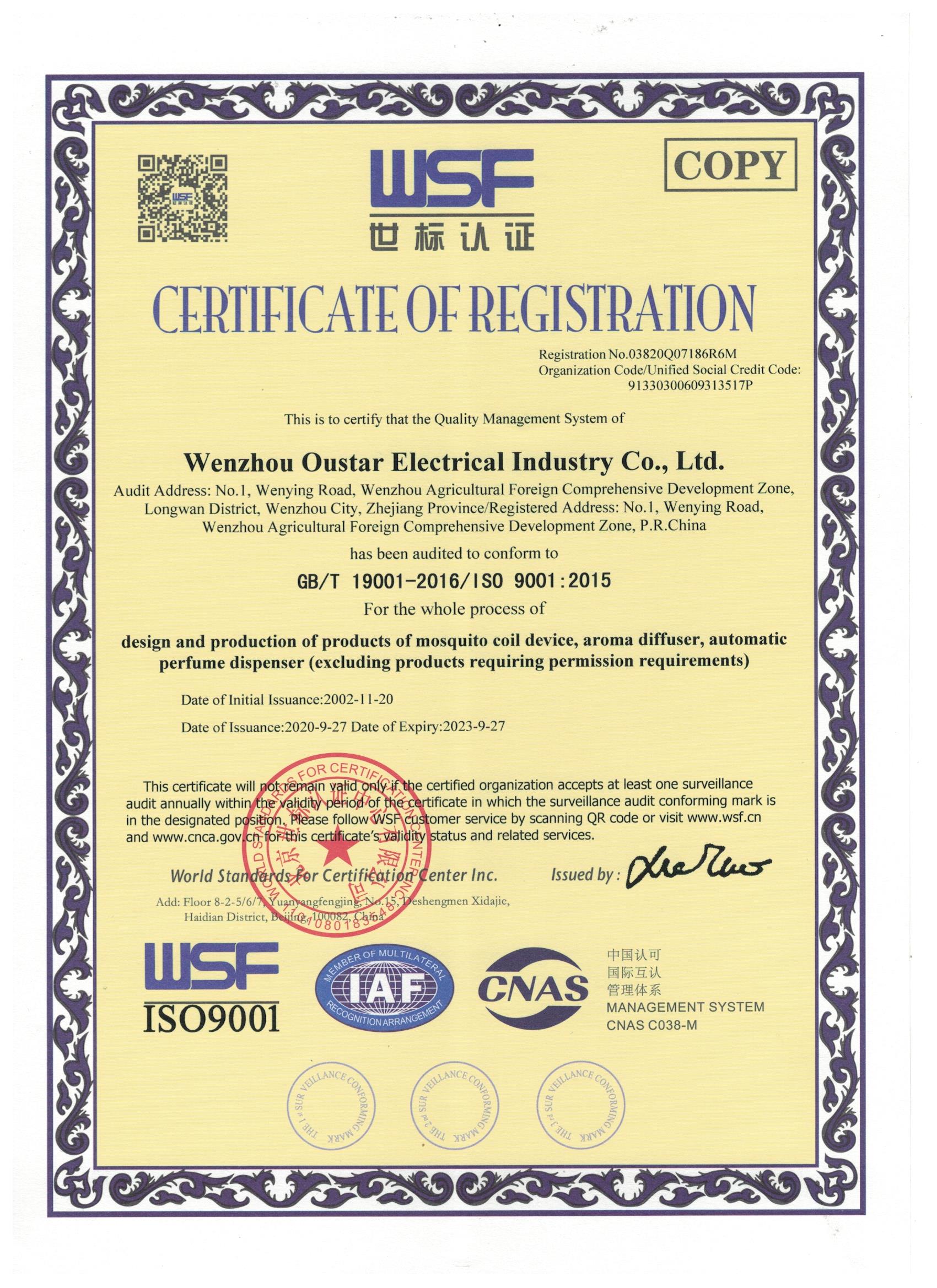

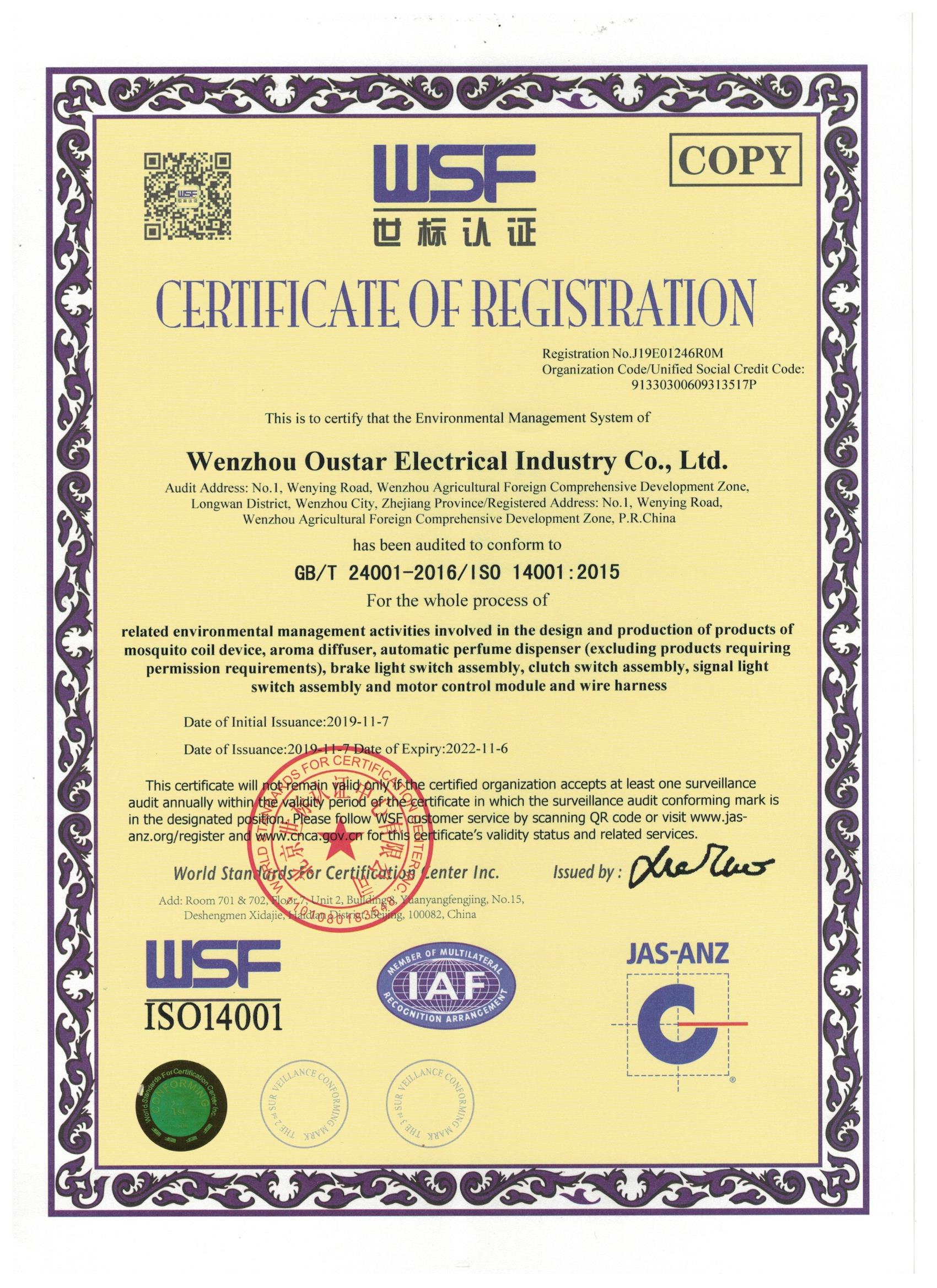

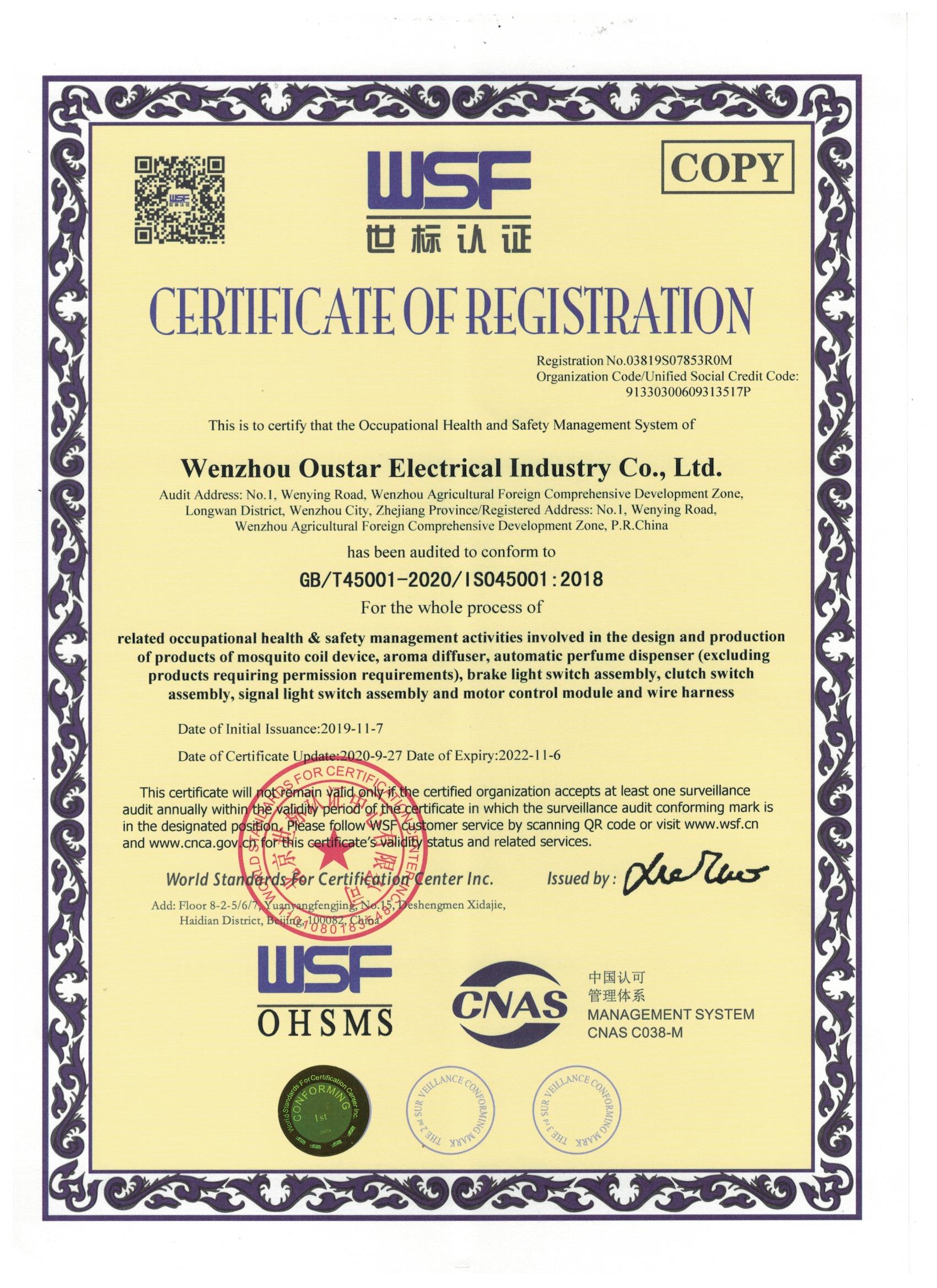

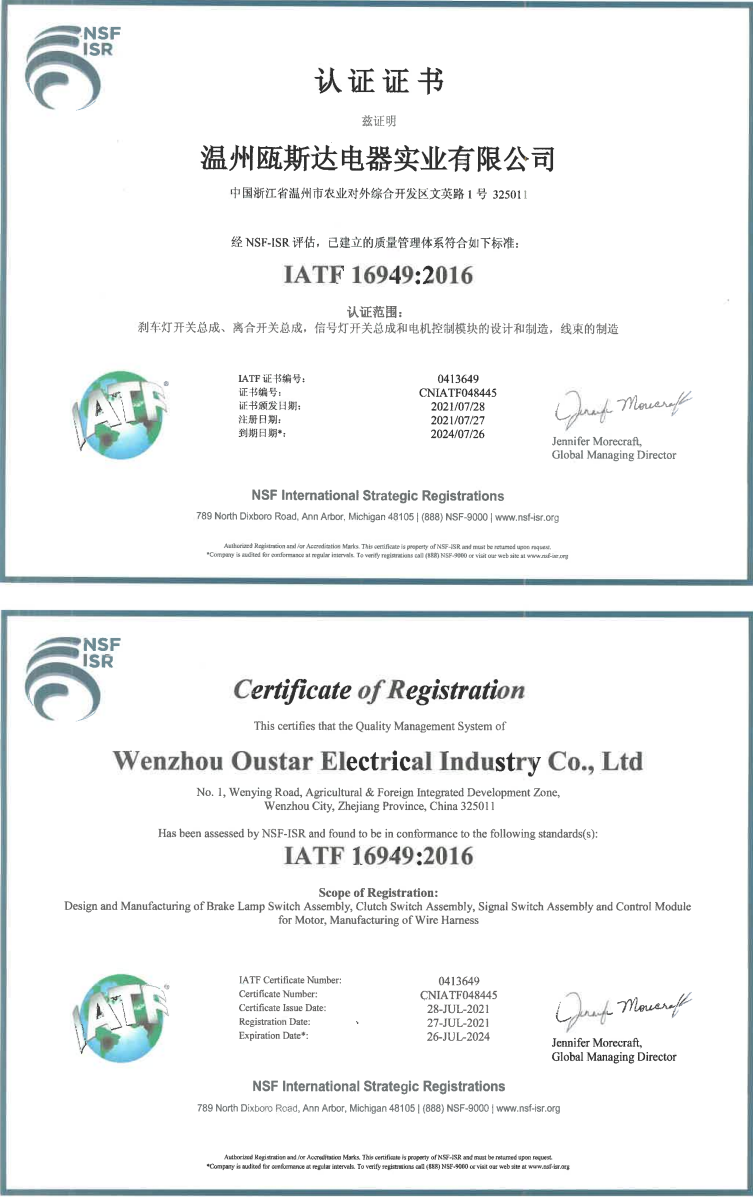

We have 700 employees in the company including 60 engineers and technicians, there are over 30 assembly lines, more than 60 computerized injection machines with 7 functional departments and 6 test labs, The company has passed with ISO14001 environmental system, IATF16949 auto quality management system certification and established a complete product research and development, production, sales and after-sales service sytstem.

PARTNER

R&D CAPABILITIES

Technology R&D is the foundation and core of the enterprise survival and development. Our company is very concerned about the construction of the R&D team. Auto parts bussiness are nearly 30 R&D personnel, including hardware engineers, software engineers, product development engineers and structural engineers. More than 90% are undergraduates or above, and more than 60% graduated from 985 and 211 colleges such as Tongji University, National University of Defense Technology, Northeastern University, Sichuan University, Jilin University of Technology, Wuhan University of Technology, Nanjing University of Science and Technology. In the next 5 years, we will maintain a growth rate of at least 10-15 new R&D personnel every year and continue to expand our R&D team to maintain our technological leading edge in the aftermarket product market involved.

Wenzhou Oustar focuses on product R&D and innovation, invests 5% of sales revenue every year for R&D, and continuously promotes and encourages product structure design and hardware And software optimization, production process rationalization and test verification rationalization, is committed to providing customers with high reliability and stability products.

Production Equipment

● Magnetizer ● Magetic Pole Balance Tester ● Automatic Winding Machine ● Airleak Tester ● Electric Coolant Pump Integrated Test Stand ● Pumps Flow Rate Test

laboratory

Roller Tester

Salt Spray Chamber

High and Low Temp Chamber

Dust Tet Chamber

Transportation Test Machine

Vibration Experiment

Develop

Surge Tester

Signal Generator

Wire Harness Tester

Digital Oscilloscope

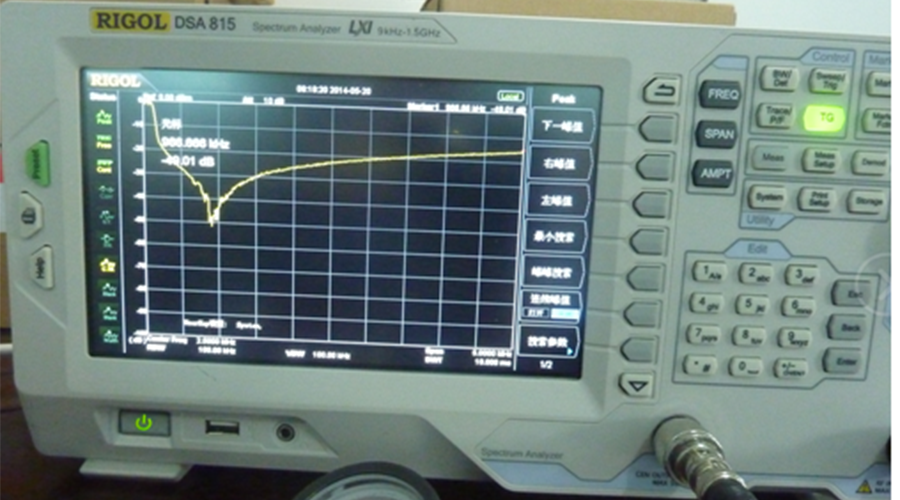

Spectrum Analyzer

Diginal Electric Bridg

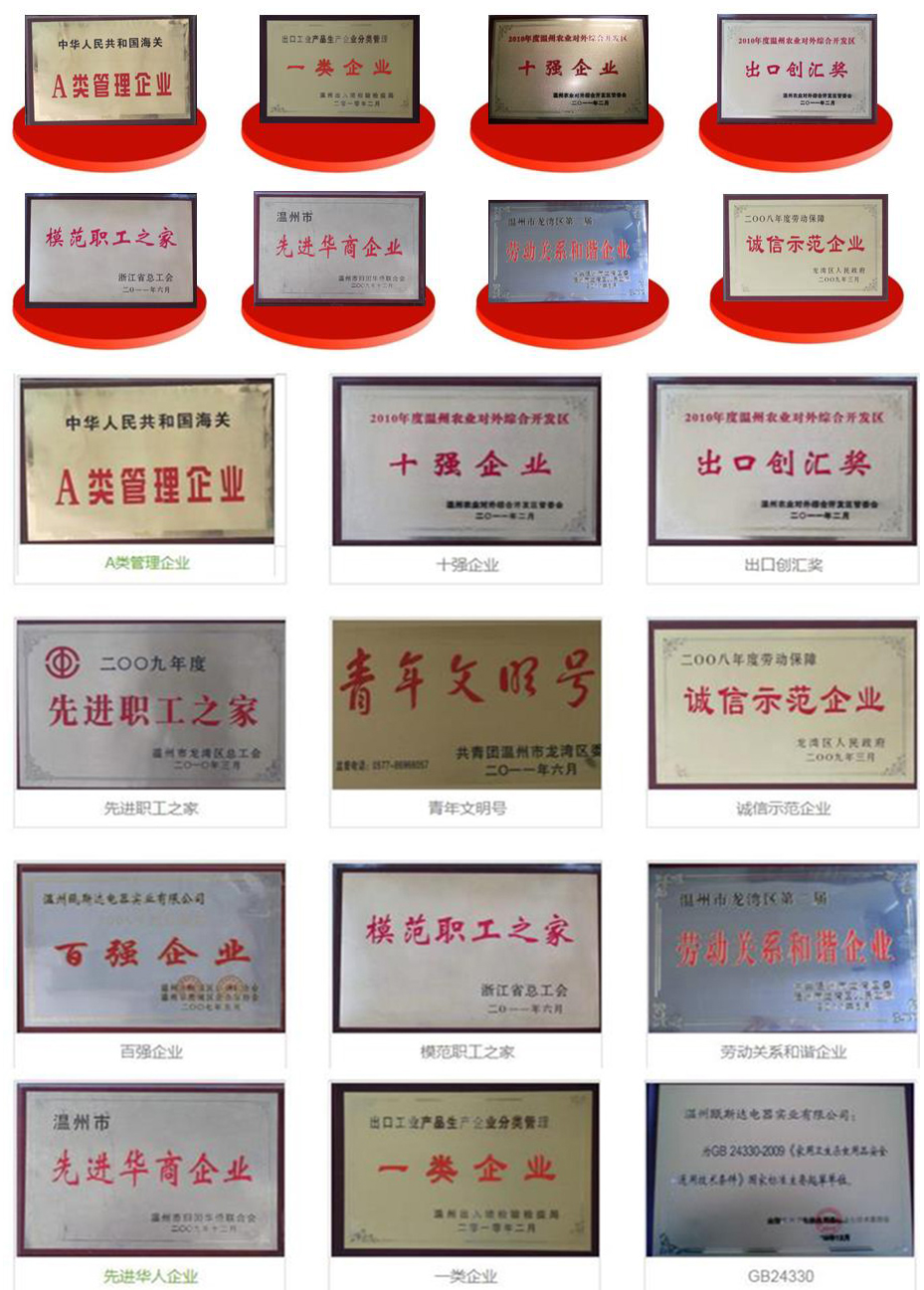

CERTIFICATE

Post time: Sep-15-2022